Sheep halal slaughter line is a complete slaughter process for sheep / goat abattoir / slaughterhouse. The line is made by a series of sheep abattoir equipment, slaughter and meat processing machine, tools and accessories.

The detailed sheep halal slaughter line is customized due to abattoir design and customers’ slaughter capacity, and budget, etc.

What are the small scale, medium scale and large scale slaughter lines?

Many owners of abattoir and slaughterhouse always ask us how much a complete sheep/goat halal slaughter line will cost. We always ask customers for their planning slaughter capacity, sizes of their slaughter area in their plant, etc.

- Small scale: several hundred heads/day or shift.

- Medium scale: 1000-2500 heads/day or shift.

- Large medium scale: over 3,000 heads/day or shift.

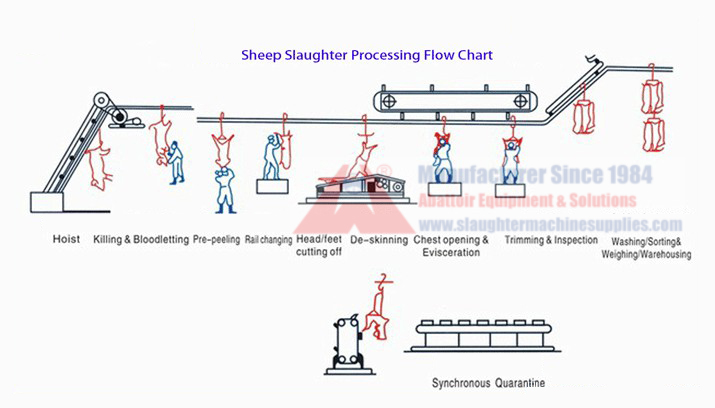

What are the general steps for sheep/ goat slaughter line?

- Holding pens managing

- Killing and bleeding

- Pre-skinning/peeling

- Rail changing

- Head/hoof cutting

- Skinning

Click here to learn more about goat / sheep dehider. - Chest opening & evisceration ( Synchronous Quarantine )

- Trimming & Inspection

- Washing/sorting/weighting/cold storage

Here is the sheep slaughter processing flow sheet:

What is the specific operation process for sheep slaughter line?

- Healthy sheep/goat enter waiting lairage or holding pens →Stop eating/drinking for 12-24h→

- Weighing →Showering before being slaughtered→

- Shackling and Hoisting→

- Killing→Bleeding(Time:6min)→

- Sheep/goat head cutting → Hind legs pre-peeling →hind legs cutting

- Front legs and chesting pre-peeling → sheep/goat skinning →

- Front legs cutting →Sealing the rectum→ Chest opening

- White viscera offal removal(Enter the tray of the white viscera quarantine conveyor to be inspected →AB)→Trichinella spiralis inspection→

- Red viscera offal removal(The red viscera is hung on the hook of the red viscera/null head quarantine conveyor to be inspected→BC)→

- Carcass quarantine →Trimming → Weighing → Washing → Chilling (0-4℃)→ Deboning → Cutting → Weighing and packaging →Freezing or keeping fresh→ Cartonning →Cold storage →Sales.

A. Qualified white viscera/offal enter the white viscera room for processing. Stomach content is transported to the waste storage room about 50 meters outside the workshop via air delivery system.

B. Unqualified carcasses, red and white viscera offal will be pulled out of the slaughtering workshop for high-temperature treatment.

C. Qualified red viscera offal will be transported to the red viscera room for processing.

We will update more knowledge about cattle slaughter line in the coming days.

hello! we are planning to build 4000sheeps slauther line so please contact with us and guide us.