What is cattle slaughter line?

Cattle slaughter line is a complete slaughter process for cattle or cows in abattoir or slaughterhouse. The line is made by a series of abattoir equipment, slaughter and meat processing machine and accessories. Of course, some machines need works to handle.

What are the small scale, medium scale and large scale slaughter lines?

Many owners and investors of abattoir and slaughterhouse always ask us how much a complete cattle slaughter line is. Actually, it depends on your daily production capacity (8 hours working time per day).

- Minimum capacity: 15-30 heads/day or shift.

- Small scale: 50-100 heads/day or shift.

- Medium scale: 150-250 heads/day or shift.

- Large medium scale: over 350 heads/day or shift.

What is the specific operation process for cattle slaughter line?

- Healthy cattle enter waiting lairage or pens→Stop eat/drink for 12-24h→

- Weighing→Showering before being slaughtered→

- Killing box(if it is halal slaughter line, there is no stunning. Then will use halal killing box)→Stunning→Hoisting→killing→Bleeding(Time:5-6min)→Electrical stimulation→

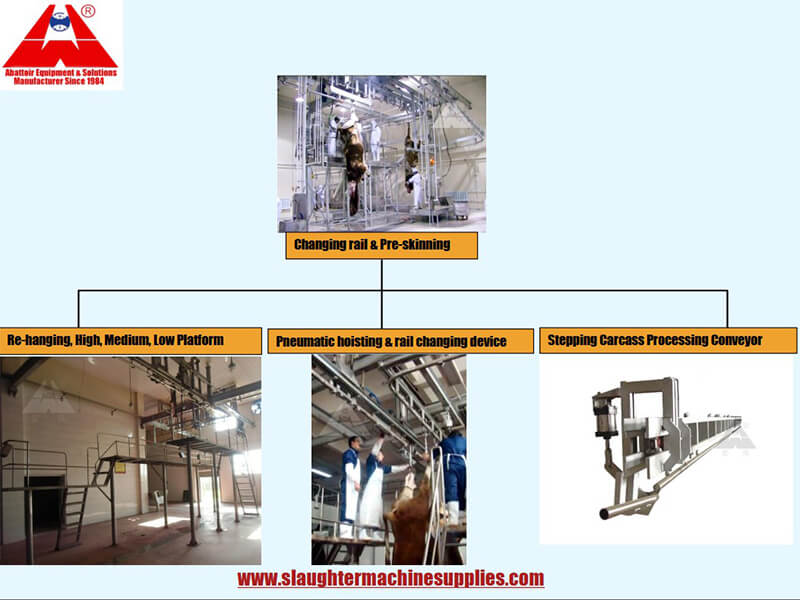

- Fore hoof and Horn cutting/Pre-peeling→Sealing the rectum→Hind hoof cutting/Rail transfer→

- Carcass railing line→Pre-peeling→Peeling/puller(The skins will be transported to a temporary storage room via air delivery system)→

- Head cutting(The cattle head is hung on the hook of the red viscera offal / the head quarantine conveyor to be inspected)→

- Sealing the esophagus→Chest opening→

- White viscera offal removal(Enter the tray of the white viscera quarantine conveyor to be inspected→AB)→

- Red viscera offal removal(The red viscera is hung on the hook of the red viscera/null head quarantine conveyor to be inspected→BC)→

- Splitting→Carcass inspection→Trimming→Weighing →Washing→Chilling (0-4℃)→Quartering→Deboning→Cutting→Weighing and packaging→Freezing or keeping fresh→ Cartonning→Cold storage→Sales.

A. Qualified white viscera/offal enter the white viscera room for processing. Stomach content is transported to the waste storage room about 50 meters outside the workshop via air delivery system.

B. Unqualified carcasses, red and white viscera offal will be pulled out of the slaughtering workshop for high-temperature treatment.

C. Qualified red viscera offal will be transported to the red viscera room for processing.

We will update more knowledge about cattle slaughter line in the coming days.

If you want more information, please contact us by email or WhatsApp. You can add our WhatsApp by scanning the QR code on the right.

Will supply us with Abattoir equipment in Zim. If so please do support our business. Kind regards.

Hi Tofara, my team will contact you soon.

Please can you email me on equipment for a 50 day Abittoir

Yes, my sales team will contact you later.

Necesitamos que nos cotizen

Our sales team will contact you soon. And you can contact us as well.

Email: [email protected]

Viber/WhatsApp number is +86 181 3678 1121

Hello…cn u plz send me the quote for minimum slaughter line complete equipment

Will contact you soon.

I am in Maseru Lesotho, can we talk privately? I am looking for a fully automated large scale cattle and sheep abattoir.

Please I’m on a project designing a Ultra modern abattoir and researching on the equipment and machines for a cattle and Sheep slaughtering.. please can I know the specifications and dimensions of this machines so as to help know the m² of the slaughter hall area

Hi dear,

I am looking to establish a modern large/medium scale cattle and sheep slaughterhouse and would like to know the price and dimensions of the complete slaughter line equipments so that the slaughterhouse will be designed accordingly.

Looking forward to hear from you asap.

Thank you.